Table of Contents

Choosing a generator isn’t only about “how many kW”, it’s about matching the generator type to your site conditions, runtime needs, noise limits, and the kind of equipment you’re powering. A small event setup may only need light, portable power, while construction sites and facilities often need longer runtime, higher output, and more durable units. If you’re comparing options locally, RR Machinery’s power generator rental is a useful starting point to understand typical use cases for worksites, events, and backup needs.

What Are Generators Used For?

Generators provide temporary or backup power when grid supply isn’t available or isn’t reliable. On worksites, they’re used to run tools, lighting, site offices, and equipment that must keep operating without interruptions. For events and facilities, generators help support essential systems and prevent downtime by keeping power available when it’s needed most.

Types of Generators

Generators come in different designs because power needs vary from one job to another. Some are built for quick, portable backup power, while others are designed for long runtimes, higher loads, or quieter operation in built-up areas. Understanding the main generator types makes it easier to match the right unit to your site, whether you’re powering light tools, running critical equipment, or supporting a full worksite setup.

Portable Generators

Portable generators are the common “move-it-when-you-need-it” option for temporary power. They’re practical for smaller site tools, short-duration backup, or event needs where flexibility and quick setup matter. They’re best when the load is moderate and the work is not continuous for long hours.

Inverter Generators

Inverter generators are chosen when you want more stable power output and typically quieter operation. They’re useful for sensitive electronics and situations where power quality matters. If you want a simple explanation of the difference, this guide on inverter generators vs traditional generators is a helpful reference.

Also Read: 5 Essential Tips for Machine Maintenance in Industrial SettingsDiesel Generators

Diesel generators are commonly used for heavier-duty requirements and longer runtime because they’re built for sustained operation and higher loads. They’re a strong match for construction sites, industrial applications, and standby power where reliability and endurance are priorities.

Standby (Fixed) Generators

Standby generators are fixed installations designed to support buildings or critical systems during outages, often with automatic start depending on the setup. They’re typically used where downtime affects safety or business continuity, rather than for mobile or short-term jobs.

Petrol (Gasoline) Generators

Petrol generators are often used for lighter loads and shorter-duration needs where portability and convenience matter. They can be a practical solution for occasional use, but they’re not always ideal for long, continuous runtime compared with heavier-duty options.

Open-Frame Generators

Open-frame generators are the basic configuration and are generally louder because the engine isn’t enclosed. They’re often used on open worksites where noise restrictions are minimal and easy access for inspection is helpful.

Silent / Canopy Generators

Silent (canopy) generators are enclosed to reduce noise and provide extra protection for components, making them better for events, built-up areas, or sites where noise control is important. If the generator will run near people, buildings, or public areas, canopy units are usually the more practical choice.

Single-Phase Generators

Single-phase generators are common for many standard loads and general site power needs. They’re often suitable for typical tools and equipment that don’t require industrial three-phase supply.

Also Read: Boom Lift vs Crane: How to Choose for Your Project

Three-Phase Generators

Three-phase generators are typically used for higher-demand equipment and more industrial applications. If you’re unsure which your site needs, this overview on single-phase vs three-phase power can help you understand what each is used for.

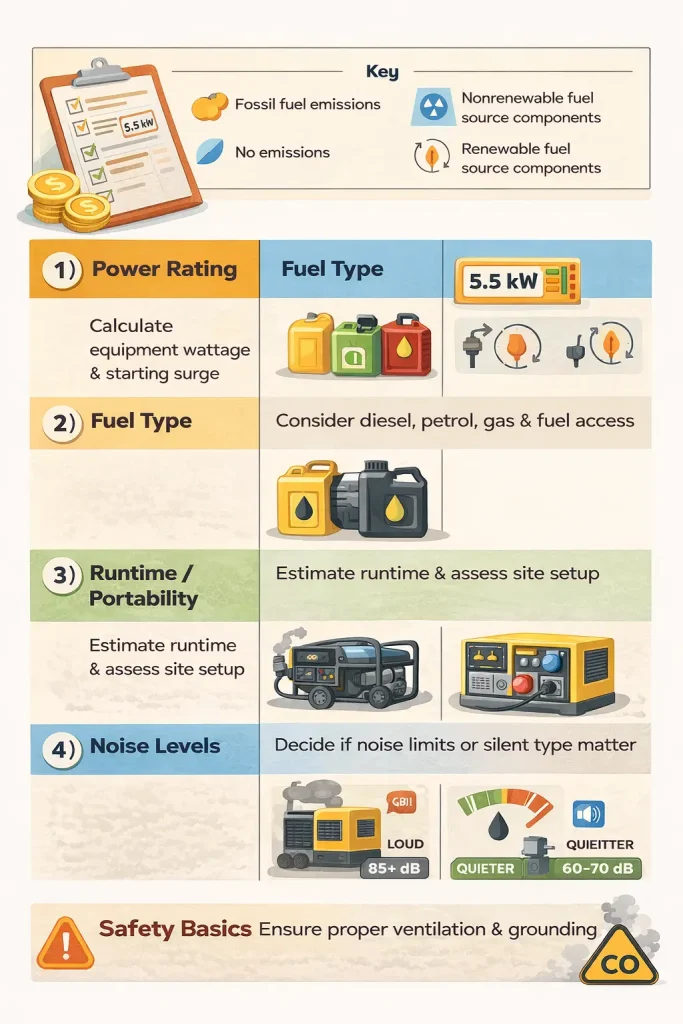

How to Choose the Right Generator Type

Start by listing what you need to run and how long you need to run it. Add up running wattage and account for starting surge (some motors and compressors draw more power at start-up). Then consider practical constraints: where the unit will sit, whether noise matters, whether you need portability, and what fuel type fits your site. Finally, confirm whether you need single-phase or three-phase output. If you need a faster shortlist, it’s usually easier to begin with available units and work backwards from your needs, RR Machinery’s rental equipment can help you compare options based on project duration and site requirements.

One more important note: generators must be used with proper ventilation because exhaust can be dangerous. The CDC’s generator safety fact sheet is a good quick reminder of carbon monoxide risks and safe placement practices.

Also Read: 7 Different Types of Forklifts You Should Know

Get the Right Generator with RR Machinery

Choosing the right generator isn’t just about kW rating or fuel type. What matters even more for day-to-day site and facility operations is having equipment that’s ready to work and backed by responsive support. With proper planning, you can reduce downtime, keep productivity steady, and keep temporary power running safely and efficiently.

Every project is different. Some teams need a short-term solution for a specific job, while others prefer longer-term arrangements or ongoing backup coverage. Many also rely on technical support and maintenance to keep equipment performing reliably over time. Working with one supplier that can support rental, sales, and servicing makes the process smoother and helps avoid delays on-site.

To explore options, you can browse power generator rental, compare rental equipment, or check sales enquiries. If you need servicing help, check Servicing & Support.

Need a quick recommendation or a quotation? Contact our team for a faster response.

Common Heavy Construction Equipment Names

Common Forklift Types and What They’re Used For