Table of Contents

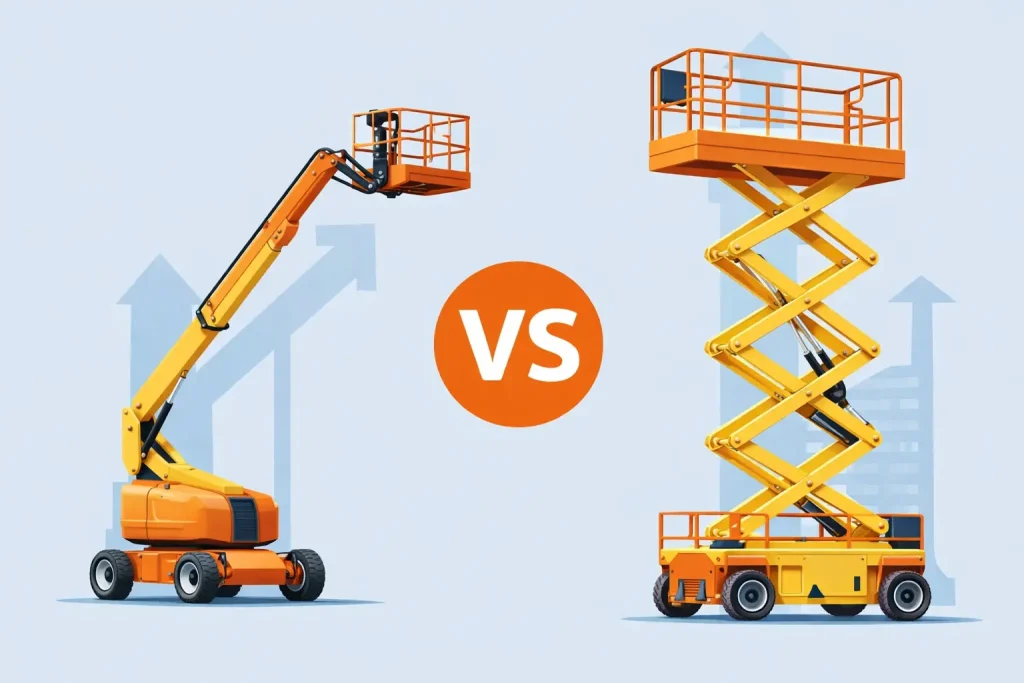

If you’re planning work at height, choosing between a boom lift and a scissor lift isn’t just a “price vs height” decision, it affects how safely you can access the work area, how often you’ll need to reposition, and how efficiently the job gets done. In simple terms: boom lifts are for reaching up and out, while scissor lifts are for going straight up. (Both fall under the broader family of access equipment often discussed as MEWPs/aerial work platforms.)

What Is a Boom Lift?

A boom lift raises a platform using an extendable arm, allowing the basket to move up, out, and around obstacles. That’s why boom lifts are commonly used for façade access, roofline work, external repairs, or any situation where you can’t park directly under the work point. A helpful way to remember this is IPAF’s classification: mobile booms are grouped under 3B categories.

What Is a Scissor Lift?

A scissor lift raises a larger platform using a folding “scissor” mechanism, and it typically moves straight up and down. This makes it a strong fit for indoor maintenance, fit-out works, M&E tasks, or repetitive jobs where the work area is directly above the machine’s position. In IPAF terms, scissor lifts are commonly grouped under Mobile Vertical (3A).

Also Read: Common Forklift Types and What They’re Used For

Key Differences at a Glance

The biggest difference is access style. Boom lifts help you reach areas that are offset or blocked by obstacles, while scissor lifts are usually better when you need stable vertical access with more platform space. In practice, scissor lifts often feel more “workbench-like” (more room for tools/materials), while boom lifts feel more “positioning-focused” (precise basket placement around structures). Manufacturers commonly frame the decision around these capability differences, reach and positioning vs straightforward vertical access.

When to Choose a Boom Lift

Choose a boom lift when the job requires outreach, for example, working along the side of a building, reaching over a canopy, accessing a point behind piping, or positioning next to racking where a straight vertical lift can’t line up. If you already know your required height and outreach, it’s easier to shortlist equipment by browsing boom lift options first, rather than trying to “make do” with a platform that can’t comfortably reach the work area.

When to Choose a Scissor Lift

Choose a scissor lift when the work is directly overhead and you want a stable, spacious platform, common for ceiling works, lighting, ducting, sprinklers, and indoor maintenance. Scissor lifts also suit repeatable workflows (“move, lift, work, lower, move again”) on flatter ground because you typically don’t need to manage outreach angles. If that sounds like your project, comparing scissor lift options helps you pick the right platform height range for your site.

Also Read: 5 Machine Maintenance Tips for Industrial Settings

Safety Considerations for Both

Regardless of type, most incidents come back to the same basics: unstable ground, overhead hazards, fall risks, and working too close to structures or moving traffic. NIOSH highlights that aerial lifts (including boom lifts and scissor lifts) expose workers to fall hazards and are used across tasks like maintenance and installation, so planning and safe work habits matter just as much as the machine choice.

For a quick, plain-language overview of common aerial lift types and how they’re generally described on job sites, OSHA’s Aerial Lifts overview is a useful reference to keep bookmarked.

Here’s a natural way to connect both internal options and an external reference in one line: when you’re deciding between boom lifts and scissor lifts, IPAF’s explanation of MEWP categories (3A vs 3B) is a quick way to sanity-check whether you need vertical access or boom outreach.

Quick Decision Checklist

If you want a fast, practical decision process, start with:

- Working height

- Whether the work point is offset (needs outreach),

- Indoor vs outdoor environment

- Ground conditions and space constraints

- Platform load (people + tools + materials).

Once those are clear, the lift choice usually becomes obvious, and you avoid wasting time on site with a machine that forces awkward positioning.

Also Read: 7 Different Types of Forklifts You Should Know

Get the Right Access Lift with RR Machinery

Choosing between a boom lift and a scissor lift isn’t just about height. What matters even more for day-to-day site and facility operations is having equipment that fits your work area, is ready to work, and is backed by responsive support. With proper planning, you can reduce downtime, keep productivity steady, and complete jobs more safely and efficiently.

Every project is different. Some teams need a short-term solution for a specific job, while others prefer to invest in ownership for long-term use. Many also rely on technical support and maintenance to keep equipment performing reliably over time. Working with one supplier that can support rental, sales, and servicing makes the process smoother and helps avoid delays on-site.

To explore options, you can browse boom lift options, compare scissor lift options, view rental equipment, or check sales enquiries. If you need servicing help, check Servicing & Support.

Need a quick recommendation or a quotation? Contact our team for a faster response.

Common Heavy Construction Equipment Names

Types of Generators and What They’re Best For